Tool storage systems and loading systems –

the TOOL terminals

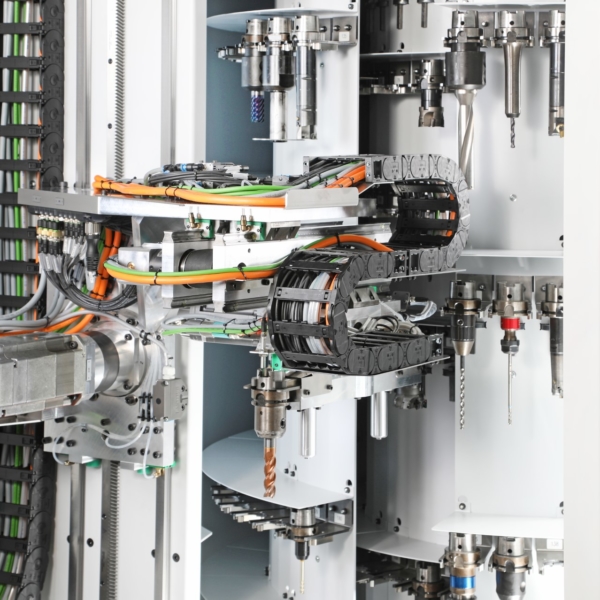

Intelligent tool handling directly on the machine

With the TOOL terminals from WASSERMANN, you switch your tools to automatic mode. You benefit from a well thought-out configuration, powerful software, and a fast, robust mechanical system. Automation and set-up during production time enable you to reduce set-up times, while the intelligent tool allocation in our software accelerates the tool changing processes.

Your advantages: more spindle hours, higher throughput, more turnover potential

Use the modular principle for configuration. Select the design of your tool storage system based on the desired capacity range. Then decide on details such as the exact capacity, mounts, tool length, and other features.

Your advantages

Develop productivity from order

- Space-saving – high tool density, e.g. 552 tools on only 3.5 m²!

- All-rounder – for all common tool mounts

- Open – storage system with interfaces to tool management, tool setup, and production

- Economical – short amortization period

- Market-oriented – complex jobs with existing machines

- Productive – reducing downtime with sister tools

- Attractive – a modern production environment for your team

- Demand-based – three basic architectures for flexible configurations

CNC automation from WASSERMANN TECHNOLOGIE GmbH

Customized solutions for your production

Why CNC automation?

CNC automation systems are the key to transforming your production process.

-

- Higher throughput – Increase the production efficiency and output of your machines with CNC automation.

-

- More spindle hours – Make optimum use of your machine capacity and maximize its service life.

-

- Better margins – Optimize economic efficiency with efficient CNC automation.

-

- No batch sizes – Efficient working already from a quantity of 1 thanks to our flexible CNC automation solutions

-

- Less skills shortage – Create modern workplaces and flexible shift models for your skilled workers.

WASSERMANN TECHNOLOGIE GmbH relies on innovative technologies to take standardized CNC automation to a new level. Our solutions minimize manual interventions while guaranteeing unparalleled precision. Use CNC automation to gain advantages for crucial key figures such as set-up times and machine running times.

A positive side effect: Your overall equipment effectiveness (OEE) will be above 80 %.

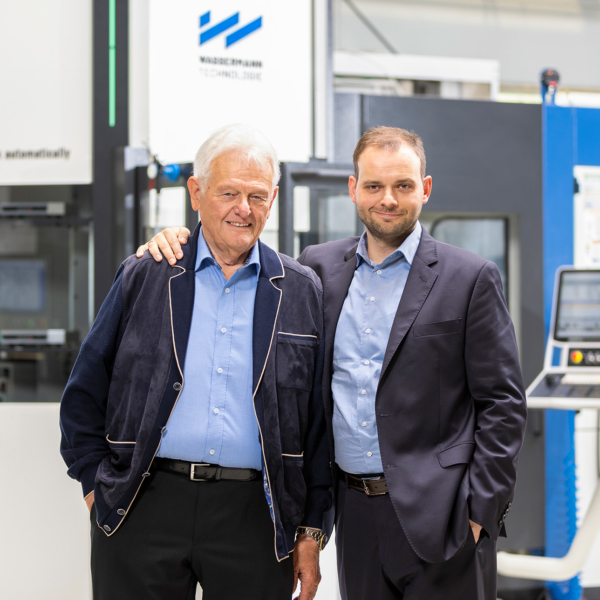

Practical CNC automation – experience meets innovation

We do not just automate – we implement well thought-out solutions.

Our decades of experience in CNC machining enable us to understand the specific requirements and to work on exactly those areas that will move your CNC manufacturing forwards. Choose CNC automation solutions that are precision-tailored, long-term, and reliable.

We not only offer comprehensive technical solutions, but also understand the requirements of your company because we have over 30 machine tools from different manufacturers in use at our own factory. With WASSERMANN TECHNOLOGIE GmbH, you can not only increase the efficiency of CNC manufacturing, but also lower your investment costs and reduce the amortization period. Choose WASSERMANN TECHNOLOGIE GmbH to increase your productivity with CNC automation systems and take your production to the next level.

WASSERMANN TECHNOLOGIE GmbH stands for customized solutions: From modernizing your complete machinery pool to optimizing existing production processes, we offer CNC automation in perfection.

Choose a CNC automation provider who not only develops, but also manufactures on a daily basis – just like you.

Efficient modernization with CNC automation

We not only deliver technical solutions, but think conceptually.

If you want to increase productivity, buying a new machine tool with integrated CNC automation is not the only option. At WASSERMANN TECHNOLOGIE GmbH, we encourage you to first check whether your existing machine can be retrofitted with a standard CNC automation system. In our experience, this is often the most cost-effective way to get more performance from your existing equipment.

In modern subtractive manufacturing, which is subject to a high level of complexity, we provide answers when machines from different manufacturers are used in production or if the available space is limited. Unleash potential with customized CNC automation.

Why automate existing machines with CNC automation?

Existing machines are often state of the art and deliver first-rate manufacturing quality. With targeted automation of tools and/or workpieces using CNC automation systems, you can increase productivity without impacting the quality of your manufactured parts.

Individual solutions for your challenges

At WASSERMANN TECHNOLOGIE GmbH, you receive not only standardized answers, but individual solutions that are precisely tailored to your setup, giving you the greatest possible benefit in terms of efficiency, investment, and amortization. We focus on meeting your requirements and offer solutions that raise your production to the next level.

With WASSERMANN TECHNOLOGIE GmbH and our CNC automation, you gain more than just productivity – you gain the future of your manufacturing.

No example projects have yet been published. Please contact us directly for more information.

TOOL-S: the economical entry-level

The round shelves with the smallest footprint and 3 to 7 levels

Your tools in the round. The TOOL-S is a round shelf storage system with 3 to 7 shelf levels. Pack up to 350 tools together on a small footprint. This gives you many times the capacity of conventional machine-adjacent magazines. TOOL-S can be run on almost any machine, allowing any production facility to implement automated tool handling or expand the machine-adjacent magazines.

You can use the modular system of TOOL-S to achieve the exact configuration for your automated tool storage system. Please contact us for an in-person consultation.

TOOL-S

- S for shelf: The compact shelf system for up to 350 tools can be combined with almost any machine.

TOOL-D: the space saver

The patented drum magazine with the highest packing density

We believe that tool availability on a machine should no longer be slowing down production. So we kept working on the problem of packing density until we found a new storage concept: TOOL-D, with a D for drum: It works with up to three drums that rotate inside one another, each with up to 6 levels. This creates space for up to 1000 tools on a very small footprint.

The standard version can already hold up to 570 tools, and with the options of the modular TOOL terminal system, you can easily adapt the capacity to your requirements.

Ask us about it. So the number of storage slots on your machine tool can no longer set the limits.

TOOL-D

- D for drum: The standard version of the space saver with patented multi-drum can hold up to 552 tools – and more on request.

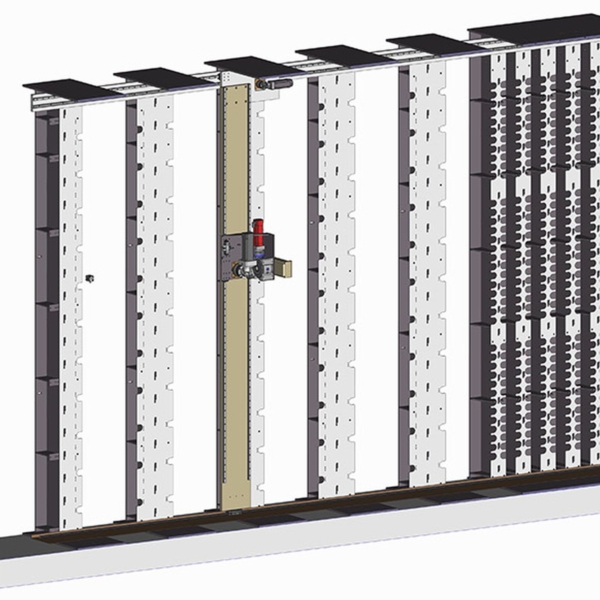

TOOL-L: the linear storage system with unlimited expansions

Simply let your storage capacities grow gradually.

Your production should have room to grow in the years to come, for example with additional machine tools, and these should ideally be able to work with more tools than specified by the manufacturer. TOOL-L gives you a solution that can grow, integrating additional machines in a linear pattern as and when required.

TOOL-L is limited only by the available space in the workshop. You can start with a capacity of 500 tools and use the modular system to expand it as required, almost without limits. The more space you have available next to your machine, the better – because this automatically increases the feasible storage capacity.

If you want maximum capacity and plenty of expansion options, please contact us about your individual TOOL-L.

TOOL-L

- L for linear: storage space for far more than 500 tools. The maximum capacity depends primarily on the available floor space.

As an additional magazine on the machine, the terminal exchanges tools with the internal magazine of the machine. There are three options for controlling the terminal.

- Without a dedicated control system:

The machine controller controls the terminal.

- With sequence controller and IO link interface:

The machine controller manages the tools.

The terminal sequence controller coordinates the handling in the terminal and the transfer of tools to the machine magazine.

- With sequence controller, own management, and IO interface:

The terminal controller controls the sequence and manages the tools in the terminal.

In addition, the terminal controller uses an interface to transfer control signals and tool data to the machine controller.

Integration of data from the tool setup is also possible.

As a direct magazine for machines without tool magazine

The terminal can be used as a direct magazine for machine tools without magazine.

This allows you to expand your production options by creating external storage slots with the terminal and automating the tool transfer. The tools are moved to the spindle directly or through an intermediate handling unit.

The terminal is controlled by the machine in this case.

As a central magazine for several manufacturing systems

As a central magazine, an individual terminal supplies the magazines of several manufacturing systems with tools to expand the storage capacities of the machines.

The terminal is equipped with a sequence controller, tool management, and an interface to the respective machine controllers. This allows control signals and tool data to be exchanged quickly and without errors. RFID technology and a link to a tool setup unit are optionally also possible.

The tools are requested either by the main computer or by the machine controller. A handling system carries out the reliable tool exchange between the terminal and the tool magazine of the connected machines.

As a stand-alone storage unit for prepared tools

As a stand-alone storage unit, a terminal is a tool storage system with a large capacity and a small footprint.

Tool data can optionally be read in via RFID without errors and the terminal uses the data to find the optimum storage slot for the tool. A tool management system can be connected at any time and data exchange with a tool setup unit is also possible. In addition to all this, the terminal can directly transfer tool data to the CNC machine digitally.

This eliminates manual input – a key cause for scrap or even crashes.