Robotics solutions

for loading tasks

Automation for large quantities and few variants

Robotics are often the right solution for workpiece automation if you are manufacturing large quantities with low variance. In these cases, robots can even be more economically efficient than clamping systems. We support you if you want to automate the loading of machines or storage systems.

We can link robots to almost any existing machine.

That means: You create a great potential for flexible application solutions. If planned correctly, you can use your robots on several systems and automate where it is most needed.

Easily expand the automation options of your machine – all the way to unmanned production. We automate the loading of our powerful terminal storage systems for your tools, pallets, and workpieces.

We help you to get the maximum impact from your robotics solution.

Keep many options open. The robot-based WORK-R meets the highest requirements in automated production. Let us talk about your expectations.

Your advantages

Immense efficiency – even for the footprint

- Space-saving – high tool density, e.g. 552 tools on only 3.5 m²!

- All-rounder – for all common tool mounts

- Open – interfaces to tool management, tool setup, and production

- Economical – short amortization period

- Market-oriented – complex jobs with existing machines

- Productive – reducing downtime with sister tools

- Attractive – a modern production environment for your team

- Demand-based – three basic architectures for flexible configurations

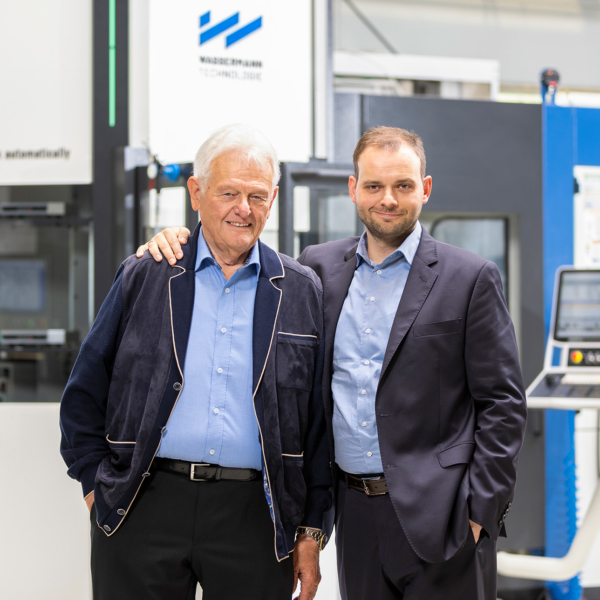

CNC automation from WASSERMANN TECHNOLOGIE GmbH

Customized solutions for your production

Why CNC automation?

CNC automation systems are the key to transforming your production process.

-

- Higher throughput – Increase the production efficiency and output of your machines with CNC automation.

-

- More spindle hours – Make optimum use of your machine capacity and maximize its service life.

-

- Better margins – Optimize economic efficiency with efficient CNC automation.

-

- No batch sizes – Efficient working already from a quantity of 1 thanks to our flexible CNC automation solutions

-

- Less skills shortage – Create modern workplaces and flexible shift models for your skilled workers.

WASSERMANN TECHNOLOGIE GmbH relies on innovative technologies to take standardized CNC automation to a new level. Our solutions minimize manual interventions while guaranteeing unparalleled precision. Use CNC automation to gain advantages for crucial key figures such as set-up times and machine running times.

A positive side effect: Your overall equipment effectiveness (OEE) will be above 80 %.

Practical CNC automation – experience meets innovation

We do not just automate – we implement well thought-out solutions.

Our decades of experience in CNC machining enable us to understand the specific requirements and to work on exactly those areas that will move your CNC manufacturing forwards. Choose CNC automation solutions that are precision-tailored, long-term, and reliable.

We not only offer comprehensive technical solutions, but also understand the requirements of your company because we have over 30 machine tools from different manufacturers in use at our own factory. With WASSERMANN TECHNOLOGIE GmbH, you can not only increase the efficiency of CNC manufacturing, but also lower your investment costs and reduce the amortization period. Choose WASSERMANN TECHNOLOGIE GmbH to increase your productivity with CNC automation systems and take your production to the next level.

WASSERMANN TECHNOLOGIE GmbH stands for customized solutions: From modernizing your complete machinery pool to optimizing existing production processes, we offer CNC automation in perfection.

Choose a CNC automation provider who not only develops, but also manufactures on a daily basis – just like you.

Efficient modernization with CNC automation

We not only deliver technical solutions, but think conceptually.

If you want to increase productivity, buying a new machine tool with integrated CNC automation is not the only option. At WASSERMANN TECHNOLOGIE GmbH, we encourage you to first check whether your existing machine can be retrofitted with a standard CNC automation system. In our experience, this is often the most cost-effective way to get more performance from your existing equipment.

In modern subtractive manufacturing, which is subject to a high level of complexity, we provide answers when machines from different manufacturers are used in production or if the available space is limited. Unleash potential with customized CNC automation.

Why automate existing machines with CNC automation?

Existing machines are often state of the art and deliver first-rate manufacturing quality. With targeted automation of tools and/or workpieces using CNC automation systems, you can increase productivity without impacting the quality of your manufactured parts.

Individual solutions for your challenges

At WASSERMANN TECHNOLOGIE GmbH, you receive not only standardized answers, but individual solutions that are precisely tailored to your setup, giving you the greatest possible benefit in terms of efficiency, investment, and amortization. We focus on meeting your requirements and offer solutions that raise your production to the next level.

With WASSERMANN TECHNOLOGIE GmbH and our CNC automation, you gain more than just productivity – you gain the future of your manufacturing.

We are already certain: We have what you are looking for.

No example projects have yet been published. Please contact us directly for more information.

Can’t see the right robotics solution? Custom solution required?

Three architectures

for your robotics solution

WORK-R: the flexible robot solutions for workpiece handling at the terminal

The WORK-R terminal from WASSERMANN is perfect for all subtractive manufacturing providers who want to automate in complex conditions.

The robot unit makes WORK-R highly versatile because it can interact with different production machines, regardless of the manufacturer. It can be used in different areas in production and meets the highest requirements for precision and versatility in automatic loading of workpieces on machine tools.

WORK-R is completely configurable. Talk to us so we can analyze together which configuration is the best for your production.

WORK-F: the combination terminal for almost anything

WORK-F is the all-round talent.

The F stands for flexible and refers to the special capability of this magazine system: It can store workpieces, pallets, and tools. With the robot add-on, you can automate loading of the terminal with these three manufacturing components.

The robot-based version also uses another great strength of WORK-F: the small footprint.

It is ideal for providing tools and workpieces for use on the machine on a very small footprint. WORK-F can be largely customized. The handling unit, for example, can be adapted to your transfer weights.

WORK-F offers you maximum flexibility for automation on a small footprint and enables more production time for your machines without personnel intervention.

With WASSERMANN, you can turn almost all corners of your workshop into a production area.

TOOL-R: robot solutions for tool handling

The TOOL-R terminal is the space-saving tool storage system.

You can use it, for example, to extend the magazine of your machine tool – with fully automated tool exchange between TOOL-R and internal magazine. Or you can use this terminal as a central tool storage system for your production.

In the TOOL-R version, you can automate loading of the magazine and tool removal. Tool handling is carried out by a robot solution. You can use our software solution for managing the tool storage system.